What Does Wedge Barriers Do?

Wiki Article

Getting The Wedge Barriers To Work

Table of ContentsNot known Facts About Wedge BarriersThe Wedge Barriers Diaries

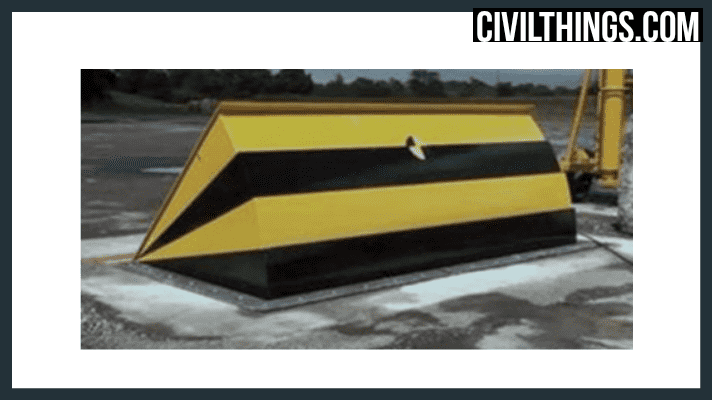

14 and the surface area 12 to which the obstacle 10 is protected might be made from concrete - Wedge Barriers. 2, the obstacle 10 is installed to or consists of a support or subframe (e. g., anchor 30 received FIG. 2 )protected under the surface area 12. The bather 10 may be bolted to the anchor or protected to the support by various other mechanical bolts. In the detailed embodiment, the obstacle 10 consists of a wedge plate 16, which includes a part that is substantially identical with the surface area 12 when the barrier 10 remains in the retracted position. Simply put, lorries or people may pass over the obstacle 10 when the obstacle 10 is in the retracted position and experience slight altitude about the surface 12 while on the barrier 10. As discussed carefully listed below, when the barrier 10 is in the released placement, the wedge plate 16 is held and supported in a raised setting by a lifting mechanism of the obstacle 10. Furthermore, the parts 18 might be bolted or otherwise mechanically combined to each other. In this manner, repair service or substitute of several parts 18 might be streamlined and streamlined. That is, fixing or replacement of solitary parts 18 may be done faster, quickly, and price effectively. FIG. In specific personifications, the anchor 30 might be a steel framework including plates, light beams(e. g., I-beams ), and/or other frameworks that are protected within the foundation 14, which might be concrete. At the surface 12, an upper side 28 of the anchor 30 might be at least partly subjected , thus making it possible for the attachment of the obstacle 10 to the anchor 30. g., threaded openings)in one or more beams or plates of the support 30 might be subjected to the surface 12. In this way, bolts 32 or other mechanical bolts may be made use of to safeguard the barrier 10 to the support 30. As the obstacle 10 is placed to the surface 12 of the foundation 14, collection of particles and various other product below the obstacle might be reduced, and components of the bather 10 may not be subjected to listed below quality environments. As suggested by referral character 52, the training mechanism 50 includes components disposed underneath the wedge plate 16. For instance, the components 52 below the wedge plate 16 might consist of an electromechanical actuator, a webcam, one or even more webcam surfaces, and so forth. Additionally, the training mechanism 50 includes a spring setting up 54

The springtime rod 58 is paired to a camera(e. g., camera 80 revealed in FIG. 4) of the lifting system 50. The springs 60 disposed regarding the spring rod 58 are held in compression by spring supports 62, consisting of a fixed spring support 64. That is, the fixed springtime assistance 64 is dealt with relative to the structure 14 and the rest of the bather 10.

The Main Principles Of Wedge Barriers

The remaining force used to the cam webcam deploy release wedge plate 16 may might provided by an electromechanical actuator 84 or other actuator. The spring try this website setting up 54 and the actuator 84(e. Wedge Barriers. g., electromechanical actuator)may operate together to translate the web cam and raise the wedge plate 16.

As pointed out over, the springtime assembly 54 puts in a continuous pressure on the web cam, while the electromechanical actuator may be controlled to exert a variable force on the web cam, thus enabling the lifting and lowering( i. e., releasing and retracting )of the wedge plate 16. In certain embodiments, the consistent force used by the springtime setting up 54 may be adjustable. g., electromechanical actuator) is handicapped. As will be appreciated, the springtime assembly 54 may be covered and secured from debris or various other components by a cover plate(e. g., cover plate go to this web-site 68 displayed in FIG. 4) that might be significantly flush with the raised surface area 38 of the structure 14. As discussed above, in the released setting, the wedge plate 16 serves to block gain access to or traveling past the barrier 10. The barrier 10(e. g., the wedge plate 16 )may obstruct pedestrians or automobiles from accessing a property or path. As reviewed over, the obstacle 10 is connected to the support 30 protected within the foundation 14,

front braces 71. As an outcome, the affiliation settings up 72 may pivot and rotate to allow the collapse and extension of the link settings up 72 throughout retraction and release of the bather 10. The affiliation settings up 72 cause movement of the wedge plate 16 to be limited. If a car is traveling towards the deployed wedge plate 16(e. For example, in one circumstance, the safety and security legs 86 might be expanded throughoutmaintenance of the barrier 10. When the security legs 86 are deployed, the safety legs 86 support the weight of the wedge plate 16 against the surface 12. As a result, the lifting device 50 might be shut off, serviced, removed, replaced, etc. FIG. 5 is partial viewpoint view of an embodiment of the surface-mounted wedge-style obstacle 10, illustrating the cam 80 and the cam surface areas 82 of the training mechanism 50. Specifically, 2 camera surfaces 82, which are referred to as reduced webcam surfaces 83, are placed below the camera 80. The lower web cam surface areas 83 may be fixed to the surface area 12 (e. For instance, the lower web cam surfaces 83 and the placing plate 85 might create a solitary piece that is secured to the support 30 by bolts or other mechanical fasteners. In addition, two cam surface areas 82, which are described as upper camera surfaces 87, are placed above the cam 80 and paired to (e. In other personifications, stepping in layers or plates may be positioned between the surface area 12 and the reduced camera surfaces 83 and/or the wedge plate 16 and the upper webcam surfaces 87 As discussed over, the cam 80 translates along the cam surfaces 82 when the wedge plate 16 is raised from the pulled back placement to the released placement. In addition, as pointed out over, the spring setting Web Site up 54 (see FIG. 3 )may offer a force acting upon the camera 80 in the direction 102 by means of spring rod 58, which may lower the force the electromechanical actuator 84 is needed to relate to the webcam 80 in order to activate and raise the wedge plate 16. 1 )to the deployed position(see FIG. 4). As revealed, the web cam 80 includes track wheels 104(e. g., rollers), which get in touch with and equate along the webcam surface areas 82 throughout procedure.

Report this wiki page